Who We Are

ASP Engineering is a manufacturer of custom made-to-drawing machined components. Our process ensures that we manufacture to match your specifications and exceed your expectations. We specialize in manufacturing small to medium quantities over an extended period of time, high volume production (50,000-100,000 pieces per year), and also prototype and R&D. Founded in 1997, we have over 20 years of experience in New Product Introduction (NPI), and supplier outsourcing for industry leaders. Today, we remain committed to delivering exceptional quality to our customers in the Silicon Valley, greater Bay Area, and beyond.

Facilities

ASP maintains San Jose, CA facilities designed to exceed customer expectations of time and quality.

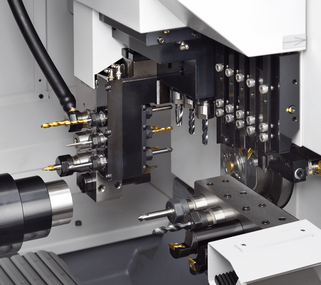

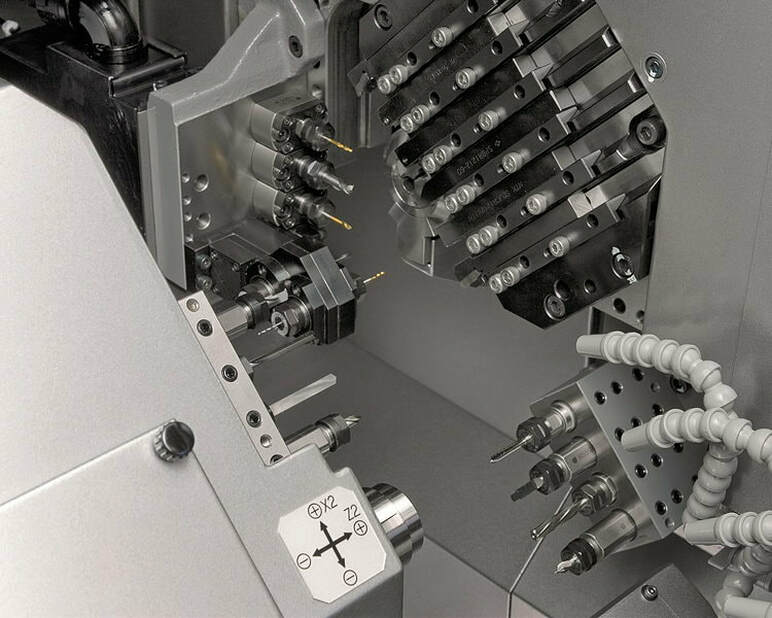

Swiss Screw Turning Machines

Our enterprise is dedicated to producing close tolerance (+/-.0005") parts using:

- Citizen Swiss-Type (Sliding Headstock) CNC Automatic Screw Lathes:

- (2) Citizen K16

- (2) Citizen 2005 & 2018 K16

- (1) Citizen 2019 L20

- (1) Citizen 2017 A20

- Machining Capability: Up to >25 mm (1 inch)

- Magazine Bar Loader

- Back Spindle and Back working

- Part Catcher and Collector

- (2) Citizen K16

- 5-Axis Machining plus live tooling

- 21 Tool Capacity

- 7-Axis Machining plus live tooling

- 23 Tool Capacity

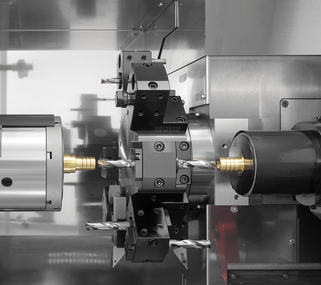

CNC Lathes

Our CNC lathes produce machined components requiring turning, threading, knurling, drilling, boring and milling in one operation.

- Miyano (Fixed Headstock) CNC Automatic Lathes: Miyano BNA 42-MSY

- Machining Capability: 42 mm (1.65 inches)

- Part Conveyor

- Magazine Bar Loader

- 8 live tools on single clutch

- Dual Spindle and Back working

- Live tooling

- CNC Turning Center

- Bar Capacity: 44 mm (1.73 inches)

- Max turning diameter: 250 mm (10.04 inches)

- Max turning length: 530 mm (20.87 inches)

- 3 Axis Machining Including, Full C-Axis

- 12 Station

- Live Tooling

Quality Assurance

ASP uses top of the line inspection equipment, which is regularly calibrated, to meet or exceed customer quality requirements. With part-specific process control, ASP checks and matches print dimensions at each step in production and undertakes final inspection with the following high-quality inspection equipment including:

- Mitutoyo Coordinate Measuring Machine

- 3 Axis

- X:28"x Y:40"x Z:24" travel

- Linear accuracy .0002"

- Resolution .00002" (0.0005 mm)

- Repeatability .0002"

- Manual Index Probe scaning for free form surfaces

- Mitutoyo Tool Maker's Microscope

- Mitutoyo Digital Drop Indicator

- Mitutoyo 24" Digital Caliper

- Mitutoyo Surface Profilometer

- Mitutoyo Micrometer Set

- Meiji Stereo Microscope

- .011"-.750" Gauge Pins- Minus Tolerance, Plus Tolerance

- Granite Plates